Creating an exquisite design is merely half the battle. You also need to comprehend how to convert that design from your computer screen to the physical world—in essence, you need to understand how to make a design suitable for print or formulate a print-ready design. This conversion could appear daunting, but fret not—we’ve assembled an array of expert tips to steer you in the right direction.

Read More: Graphic design trends 2024

Contents

Why Print Preparation Matters

Appropriate print preparation is pivotal in transforming a design from a digital format to a physical print product, creating the best print design. This transition can significantly influence the final output of your printed piece. A well-prepared design, or a print-ready file, helps ensure your print is of high quality, cohesive, and professional. By suitably preparing your printing design, you minimize the chance of errors, mismatches of colours, and unexpected issues when the final print is produced.

The Fundamentals of Resolution and Colour

In the printing design process, resolution and colour are two significant factors. Resolution refers to an image’s detail level, usually expressed in dots per inch (DPI). For a good print design, a high resolution of around 300 DPI is necessary to have a sharp and clean image. Meanwhile, a lower resolution of around 72 DPI is typically used for web design.

The difference between how printers and computers interpret colours is crucial. Printers use the CMYK system (cyan, magenta, yellow, and key—meaning black). Your computer screen uses the RGB (Red, Green, Blue) system. Therefore, when your design is ready for printing, you need to modify your design colour scheme from RGB to CMYK.

Read More: How to Choose the Right Brand Colours

Include Bleeds

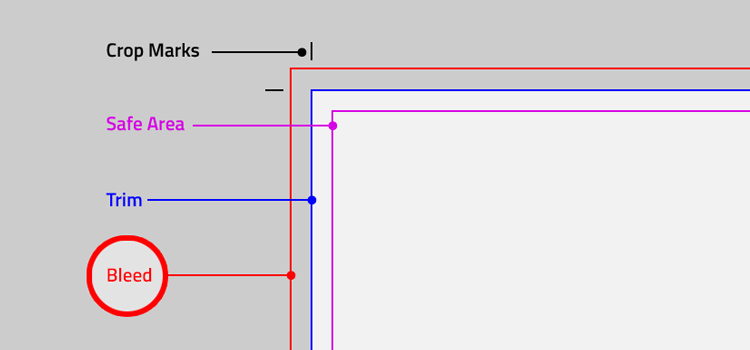

Bleeds are a significant aspect of design for printing that extends to where the printer will cut the paper. They are critical to ensuring the final printed material appears professional and polished. If not included, unwanted white edges might appear, notably affecting the overall appearance of your print. The industry standard is to leave roughly 0.125 inches of bleed area on all sides of your design. This area will be trimmed off during the cutting process, but it is mandatory to ensure vital aspects of your design aren’t incorrectly cut. Ruler guides in your design tool or software are beneficial when determining the bleed area, simplifying your task!

Attending to Fonts

When you are preparing a print-ready file, it’s essential to either embed your fonts or convert them into outlines. This step helps to preserve your design exactly as you intended, even if the printer does not support the font used in your design. Fonts that are embedded or outlined become part of the artwork, preventing them from changing during the printing process. The importance of font size should not be underestimated. Too small, and your text may be difficult to read. Too large, and it might overpower the design and make it less visually attractive. Therefore, select the font size wisely to retain balance in your design for printing.

Use High-Quality Images

In printing, the image quality you use in your design for printing can significantly impact your project. Should your image quality be subpar, with flaws such as blurriness or pixelation, these defects will be noticeably amplified on paper. This can severely undermine your design’s appearance, making it seem unprofessional or sloppy. Therefore, it is crucial to use high-resolution photos in your work that contribute to a crisp and clear print result. Reliable sources should be used for image retrieval, ensuring they are good print design materials.

Employ Vector Graphics

Raster images, or regular images, can sometimes turn blurry or grainy when altered in size, as they are formed from small squares, or pixels. Conversely, vector graphics do not carry this drawback. They use mathematical formulas to construct shapes, meaning they can be resized without a loss of quality. This characteristic makes them ideal for designs formatted for print.

Select the Right Material

Choosing the correct material for print, also known as the substrate, significantly affects the final appearance of your print-ready design. The weight of the substrate, its texture (smooth or rough), and the finish (glossy or matte) can noticeably enhance your print design. However, these choices must not detract from your design but must complement it. Picking the right material can take your print design to the next level!

Obtain a Proof

Producing a proof, a practice version of your design, allows you to preview your work before it becomes a print-ready file. Proofs give you a final opportunity to identify errors or make any last tweaks. This way, you can guarantee complete satisfaction with your design before printing in bulk.

Familiarize Yourself With Your Printer’s Specifications

Each printer has its unique features and specifications, and knowing these specifications can simplify the print process. Understanding the printer’s specifics can be achieved by visiting the printer’s website, speaking to a staff member, or contacting customer support. This knowledge can enhance your printing experience, leading to better outcomes for your designs.

Read More: 5 Simple Steps to Preparing Your Files for Print

Conclusion

Preparing a print design requires patience, finesse, and some experimentation. However, with these expert-endorsed steps, you are sure to succeed. While creating an outstanding design is the first step, your end goal should be to materialize that design in print, bringing your hard work to life. So, are you ready for printing? Let your creativity loose, start designing, and here’s to impeccable printing!

We hope you find this content from Butterfly GP useful. Please share your views with us.